1 Cause Analysis

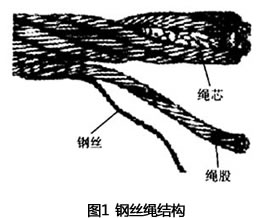

With the continuous improvement and progress of production technology and social philosophy, safety production has been paid more and more attention, and the mechanical and electrical safety protection of the mining system is becoming increasingly perfect. For the reason, during the operation of the mine improvement system, the wire rope was often pulled off due to the impact of external forces, causing major malignant accidents such as broken ropes and squats. Essence The steel wire rope structure is shown in Figure 1. Steel wire rope lossless detection

In the process of improving the system operation, the wire rope understands the broken wire, rust, and corrosion of the steel rope, which is of great significance for the safe operation of the rated machine. Usually, we use the daily use of the naked eye and the label caliper to determine the changing trend of the wire rope during the improvement process. There are many disadvantages to see the surface corrosion and cutting of the wire rope, and there are many disadvantages.

(1) Observing the wire rope with the naked eye, you can only see the surface change trend of the wire rope, and you cannot see the inner wire of the wire rope.

(2) To measure the wire rope with a gigarette calibration, you can only measure the broken wires and disconnection of the steel wire rope one by one, and the full rope can be measured.

Therefore, based on this situation, the system that can conduct a system that can comprehensively automatically detect the operation of the rope of the wire rope full rope is imperative.

2 TCK.W wire rope online automatic monitoring system overview

TCK.W wire rope online automatic monitoring system adopts weak magnetic detection technology, using the changes in the spatial magnetic field vector situation and the operation of the operation of the wire rope to detect the magnetic signal on the wire rope, so as to realize the changes in various damage changes such as wire rope wire, rust, fatigue wear and other damage changes. Online detection and precise positioning, finally print text reports. The monitoring system can be widely used on the steel wire rope of the lift transportation machinery in the mines, port loading and unloading machinery, construction, tourism and other industries.

2.1 working principle

According to the on -site inspection, the detection device is installed at the auxiliary manhole manhole rack. The detection device is well installed and reliable. The wire rope can flexibly detect the device. , Using weak magnetic detection technology, using the changes in the spatial magnetic field vector situation and the law of operation of the operation of the magnetic signal on the wire rope. The device is connected to the secondary station through the data cable. Connect the power cord. Open the detection probe so that the wire rope is at the center of the detection probe, loosen the detection probe, and the detection device moves simultaneously with the operation of the wire rope. During the detection, the detection of the effective section of the steel wire metal metal metal with the detection probe is detected. The conversion, finally the detected information was transported to the main control station, and then the main control station conducted a comprehensive comprehensive analysis of the detection information. In the end, the monitoring report of various damage such as the wire rope, rust, and wear of the wire rope.

2.2 System functions

(1) The detection device uses a dedicated sensor to accurately detect damage to the wire rope, rust, fatigue and other damage;

(2) The second -level station uses the A/D sampling chip with ARM single -chip microcomputer and 12 -bit accuracy to achieve high -precision mold conversion;

(3) The main control station is the nerve center of the entire monitoring system. It can comprehensively analyze the detection information. It can provide daily analysis and processing results and the damage change trend of the wire rope to achieve online real -time monitoring.

2.3 System Features

(1) Real -time online monitoring of full -rope, no parking, no affecting production, no harm to the human body;

(2) It does not affect the normal operation of other equipment and does not affect the surrounding environment;

(3) The temperature of the working environment is between -20 ~+40 ℃;

(4) According to the daily monitoring situation, you can judge the trend of steel wire ropes, corrosion, and rust to the trend of rope, and eliminate hidden dangers in advance to ensure safe production;

(5) Optimized human -computer engineering, realizing easy operation, impeccable appearance, and creative structural design, reflecting the simplification and efficient concept of aggregate industrial products;

(6) Solve a series of problems such as follow -up ride ride rope rope and large jumping rope and large jump.

2.4 System operation

(1) Double -click the computer desktop icon to run the "TCK.W wire rope online real -time security detection management system" and enter the main interface of the system.

The information bar and the function buttons are composed of 4 parts. It mainly displays the wire damage curve of the wire rope in real time, and uses the function button to establish the function of the steel wire rope target file, system calibration, detection, stop, and the damage curve and damage data of the wire rope.

(2) Login system. Enter the corresponding password to protect the security of the information and prevent the misunderstanding of non -operators, and the system passes the password certification.

(3) Set the current goal. Setting the goal is to put the related data together, and then get accurate analysis results.

(4) Return to the main interface of the system, click the "Detection" button, and the system starts to detect the steel wire rope; click the "Stop" button to stop the detection of the system and automatically save the collection data. During the detection process, the curve display area of the main interface of the system shows the detected damage curve in real time.

(5) View results. In "results", we can clearly check the damage curve and daily record value and print them.

(6) View data. In "Data", we can clearly see various damage data results.

3 Application prospect

Our group company coal -tongkou ore ore, swallow mountain mine, horse spine ore, etc. are installed and used by TCK.W wire rope online automatic monitoring device. The operation is normal to this day. Real -time monitoring of the full rope of the wire rope is high. The normal and safe operation of the rangers is guaranteed to ensure the safe production of coal mines and have a broad market promotion prospect.

上一篇: 机电一体化产品在落陵煤矿生产中的应用

The application of TCK.W wire rope detection technology in academic journals

Editor's note: TCK.W has developed a weak magnetic rope detection technology that can real-time monitor the status of steel ropes 24 hours a day, 365 days a year, and locate, classify, and quantitatively identify various internal and external defects. Currently, more than 2,500 clients in 42 countries worldwide are using this technology. These clients have published papers on the safety and economic benefits brought about by this new technology in various academic journals. Here is a compilation of some of these papers for experts and scholars to explore and study in depth.。

论文名称

作者单位

发表期刊:"Me

发表期刊:"Me