Products

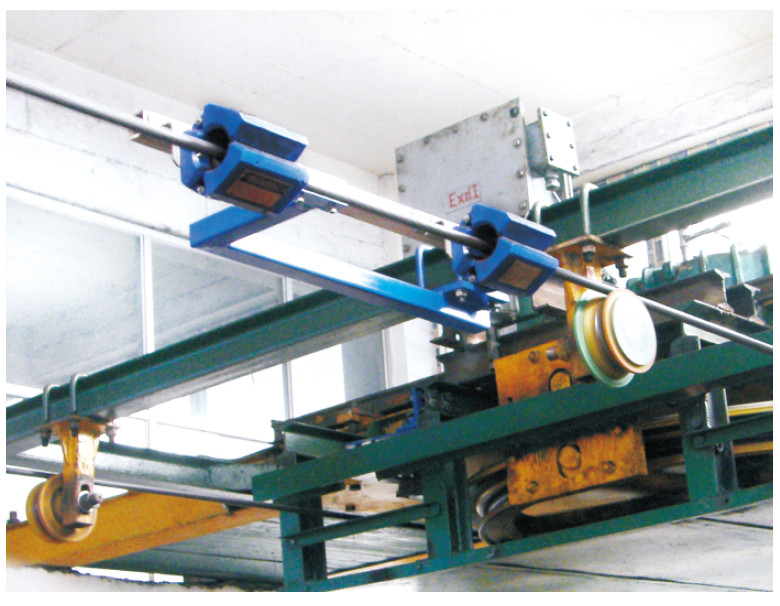

●TCK.W Industrial Internet + magnetic memory AI weak magnetic detection technology + machine vision recognition intelligent monitoring technology to strengthen safety production

●Enhance the ability of perception, monitoring, early warning, disposal and evaluation in the safe operation of wire rope throughout its life cycle

●To realize the transformation from static analysis to dynamic perception, post-emergency to pre-prevention, manual detection to intelligent monitoring

●It has created great value in energy saving and emission reduction, cost reduction and efficiency increase, machine replacement, and realization of double carbon goals.

Wire rope safety solutions >>

- Core technology

- Technical principle

- Technical parameter