转载自《煤矿机电》 作者 郭东兵

钢丝绳芯输送带在线实时自动监测系统的开发及应用

摘要:基于TCK.W弱磁检测技术,研制了TCK.W钢丝绳芯输送带在线实时自动监测系统,可实现

对输送带内部断绳、锈腐蚀、接头位移、压伤等隐蔽故障的定位、定性及定量检测。经实际应用,该系统不仅具有检测精度高、操作简便、低能耗、零污染等突出特点,而且在减轻钢丝绳芯输送带检修作业强度的同时,对预防横向断带事故起到重要的技术保障作用,同时还创造了可观的经济效益。

关键词:在线自动监测;弱磁检测技术;钢丝绳芯输送带

中图分类号:TM247;TM936 文献标识码:B 文章编号:1001—0874(2011)03—044—03

DevelopmentandApplicationofOn--LineReal—TimeAutomatic

MonitoringSystemofSteelWireRopeCoreConveyorBelt

GUODong—bing,LIHuin,DOUBo—lin

(1.JingchengLanyanCoalCo.,Ltd.,Jincheng048006,China;

2.LuoyangTixikaiSteelWireRopeDetectingTechnologyCo.,Ltd.,Luoyang471003,China)

Abstract:The on-line real-time automatic monitoring system of TCK.W steel wire rope core conveyor belt is being researched and developed based on TCK.W weak magnetic detecting technique,which can realize the positioning qualitative and quantitative detecting of hidden faults in the conveyor belt such as broken ropes,corrosion,joint displacement and crushing.By practical application,this system has the features of high accuracy,easy operation,low power consumption and zero contamination.This system reduces lateral direction belt broken accident while Reducing the detecting operating strength of steel core conveyor belt.And it creates obviously economy effect.

Keywords:online automatic monitoring weak magnetic detecting technique steel wire rope conveyor belt.

1 概述

钢丝绳芯输送带长期处于大运量、长距离和重负荷的连续运行状态下,尤其是在工况较恶劣的条件下运输,时常会出现接头抽动、钢丝绳被意外砸断、输送带严重跑偏以及钢丝绳锈蚀和疲劳等现象,一旦发生横向断带或纵向撕裂等安全事故,将直接影响企业的安全生产与经济效益。河南某大型国有矿业集团在过去10年问,共发生输送机断带事故24起,累计影响生产时间超过1800h,其中15起断带发生在接头处,占了断带总数的60%。事故不仅造成大量的经济损失,更是造成了人员伤亡。由于输送带的钢丝绳芯嵌于输送带之间,若要实现对其检测,最关键是能够感应和可靠提取钢丝绳芯的原始损伤信号。传统磁检测方法的传感器灵敏度低,并要求仪器必须贴近被测物才能检测,故无法实现钢丝绳芯输送带在线监测。

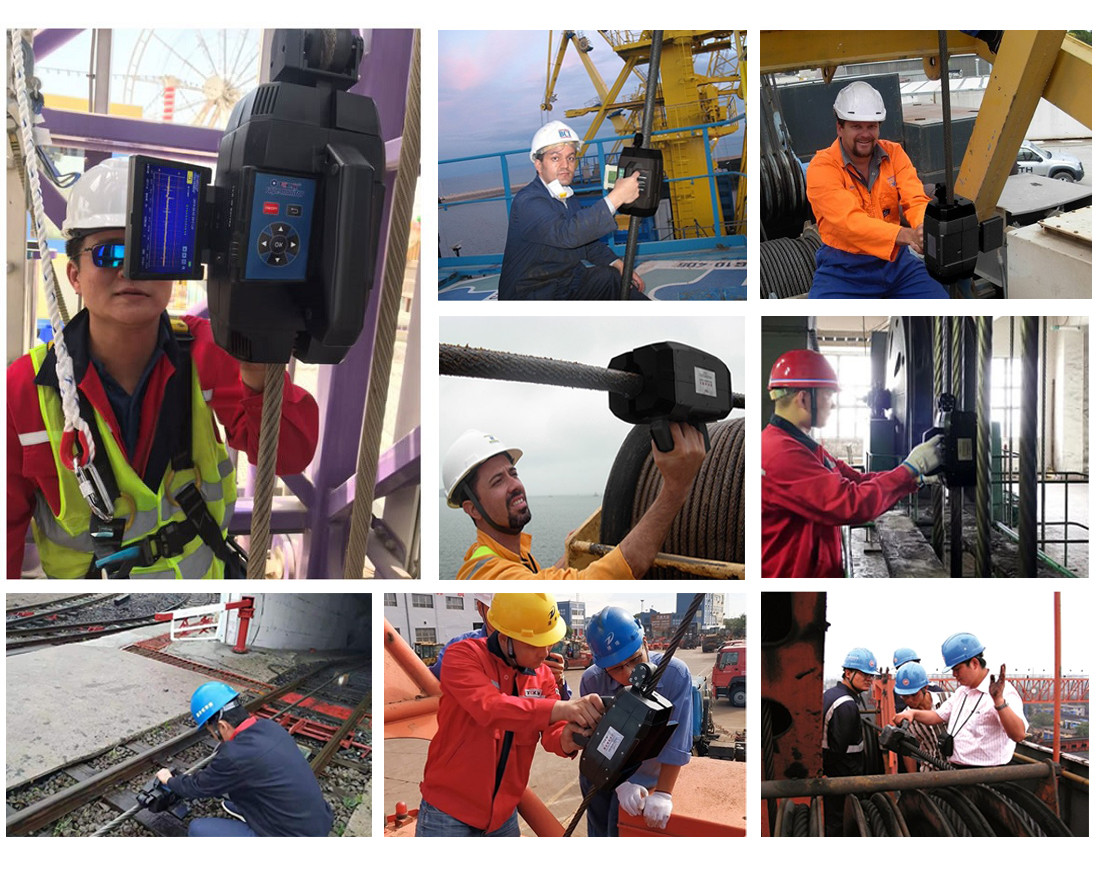

以TCK.W钢丝绳弱磁检测技术为核心,晋城蓝焰煤业公司与洛阳TCK.W钢丝绳检测技术公司联合开发出TCK.W钢丝绳芯输送带在线实时自动监测系统,成功解决了在线检测钢丝绳芯输送带的接头位移、断芯、磨损、锈蚀、疲劳等故障的技术难题,创造了一种全新的安全监管模式。该系统不仅能够实时监测输送带使用过程中的安全状况,消除事故隐患,提高煤矿钢丝绳芯输送带的现代化管理水平,而且可以科学降低输送带的使用成本,有效地提高了输送带的运行效率。

2 TCK.W钢丝绳芯输送带在线实时自动监测系统

钢丝绳芯输送带在线自动监测系统的技术关键在于采用了高灵敏的传感器技术,由于TCK.W传感器的灵敏度可达50V/mT,能感应地磁场变化,其灵敏度是霍尔元件的25万倍,是霍尔组件的7.14万倍,因此其检测装置采取“宽距”非接触检测,与输送带之间的距离已达到100mm。这从根本上解决了对输送带在线检测的关键难题,进而实现了对输送带钢丝绳芯在线实时定量、定性、定位检测。

(1)系统构成

TCK.W钢丝绳芯输送带在线实时自动监测系统主要由TCK.W-GMS型弱磁加载装置、TCK.W—GMS型探伤检测装置、TCK.W-GMS型行程编码器、TCK.W自控式声光报警装置及TCK.W多信道终端主控装置等5部分构成。

(2)系统技术流程

1)TCK.W-GMS型弱磁加载装置。监测系统能主要对输送带钢丝绳芯进行弱磁规划,使输送带处于稳定的待测状态。

2)TCK.W-GMS型探伤检测装置。提取输送带钢丝绳芯技术状态原始信号,完成规定的数模和信息制式转换,并对原始数据初步处理和信息存储,再通过有线或无线的通讯传输方式,将钢丝绳芯损伤信号实时传输给终端主控装置。

3)TCK.W-GMS型行程编码器。主要测量钢丝绳芯输送带的带速和行程,并将高密度采样脉冲信号输入探伤检测装置。

4)TCK.W自控式声光报警装置。根据探伤检测装置的检测信号处理结果实时报警,其绿灯表示钢丝绳芯输送带处于安全状态;黄灯表示钢丝绳芯输送带存在局部隐患,需加强关注和维护;红灯则表示钢丝绳芯输送带存在显著险情,处于危险状态,需立即采取停车调整、更换新带等预设的应急预案。

5)TCK.W多信道终端主控装置。这是本系统的中枢,由中央处理组件、硬件系统、软件系统和显示终端等组成。它能对收到的检测信号进行全面的综合分析,并将每日的分析处理结果存人数据库,以便随时检索查询,显示终端可实施查询或打印检测数据分析报告,清晰完整地为用户展现钢丝绳芯输送带的实际安全状态和损伤发展趋势。

3 主要特点及技术性能

(1)主要特点

1) 采用TCK.W弱磁检测技术。可完成对钢丝绳芯输送带各种损伤高可靠性和高精度的定量和定位在线自动检测。

2) 高灵敏度检测器远离输送带。它不受输送带运行的带速变化、上下抖动、跑偏等因素影响,采用了单元式组合设计,不受输送带宽度的限制,且安装灵活方便。其软件采用功能模块化设计理念,人机界面友好,操作简便。

3) 满足井下防爆和煤矿各项技术要求。不仅适用于煤矿井下使用,也适合于露天等其它恶劣工况现场的全天候在线监测。无需人工值守,检测过程与输送带运行同步在线实时完成,确保人身安全。

4) 实现数据存储。可完成对原始数据的实时处理、实时传输和实时曲线/图像显示,实现数据压缩和大数据量的存储,便于历史记录、事后分析和重放,并实时提供钢丝绳芯输送带各类损伤的检测结论、损伤等级、损伤类型分析等,还具有实时声光报警提示功能。

5) 有联动功能。能够实现与用户控制设备的联动功能。

(2) 技术性能

1) 准确检测输送带钢丝绳芯接头、断绳、锈腐蚀等损伤程度。经工业现场的试验对比和分析统计,该系统的接头、断绳实时检出率达到100%,而且能够准确识别接头阶数和断绳根数;其它损伤实时检出率>95%。

2) 金属截面积损伤定量检测误差小。通过对输送带样本预埋钢芯损伤,再实施在线检测的方式,验证了该系统对钢丝绳芯50%~90%程度范围内金属截面积损失的检测误差小于5%。

3) 定位分辨率高。对所测损伤点报警位置进行验证,该系统对钢丝绳芯损伤的定位分辨率达到1mm,可准确监测钢芯接头位移量。

4) 不受输送带运行速度的影响。该系统采用空域采样方法,无论输送带运行速度的快慢,都能精确完成检测任务。

5) 满足各种宽度规格钢芯输送带的检测需要。成庄矿实施监测的运煤主输送带有1400mm宽度,实际采用2个并排的检测单元,每个单元可覆盖800mm带宽,故对于大量不同宽度规格的钢芯输送带,只需要根据实际情况采用相应数量的单元组合,就能满足对具体目标的在线实时监测,对于用户而言既经济又实用。

4 应用效果

TCK.W钢丝绳芯输送带在线实时自动监测在成庄矿应用一年多来,对自用的钢丝绳芯输送带实现了一种无纸化安全监控的创新监管模式,创造了可观的经济和社会综合效益。

(1)生产效率提高

成庄矿带式输送机长度为2670in,上下带总长5400m,日常带速为3.6~4m/s。若人工检查时带速在0.5nr/s左右,全程人工肉眼检查一遍至少需3h,而且无法检测出对钢丝绳芯的接头抽动、钢芯断裂、严重锈蚀和疲劳等损伤;采用x光成像检测方法,仍不能快速可靠鉴定全程输送带的安全状况,而且检查时,常常挤占正常生产与正常检修时间,严

重影响了主斜井带式输送机的生产效率。采用在线实时自动监测系统后,运输和检测同步进行,不仅克服了以前外观检查的固有缺陷,而且极大地延长了生产时间。一年可多运煤67200t,年新增利润873.6万元。

(2) 节能降耗

钢丝芯输送带检验过程中产生的动力能耗主要包括输送机能耗和检测设备使用成本。输送机驱动电机总的空载负荷为750kW,在每年576h开机检查过程中,实际消耗电能达43.2万kWh,按目前工业电价0.53f~/kWh计算,每年就需23万元。应用该系统后,由于该系统的功耗<200W,全年产生的电费几乎可以忽略不计,不仅避免了输送机的空转能耗,而且减少了输送机的启停次数和延长了设备的使用寿命。

(3) 节约设备费用

该系统能够对输送带各种损伤的安全隐患进行实时诊断和及时预报,杜绝了因盲目检修和更新输送带而造成浪费。使用该系统后,还可以为钢丝绳芯输送带的报废更新提供重要技术依据,从而能合理延长输送带和输送机整机的使用寿命。

5 结语

TCK.W钢丝绳芯输送带在线实时自动监测系统通过晋城煤业集团公司成庄矿一年多的实际应用,能实时监测钢丝绳芯输送带的安全状态,可靠预防断带事故,科学降低钢丝绳芯输送带使用成本,有效提高设备运行效率,不仅在技术上达到国内外领先水平,而且具有十分突出的应用前景和使用价值。该装置初期投入30万元,一年为企业创造近1100万元的直接经济效益。

参考文献:

[1]盂国营,方佳雨.钢芯输送带接头损坏原因及一次破断试验研究[J].煤炭科学技术,2003(9).

[2]兰西柱.钢芯输送带接头断裂在线监测仪的研制[J].煤炭科学技术,2000(12).

[3]程山.无损探伤检测立井钢丝绳的方法[J].煤矿机电,2009(1).

[4]乔巨忠.强力输送带无损探伤仪的研制[J].山西焦煤科技,2005(3).

[5]刘泽宇.钢丝绳芯胶带实时在线检测仪的应用[J].煤矿开采,2006(3).

[6]JEONGGeun-Young,et a1.ARM7 compatible 32一bit R1SC proces—sor design and verification[C].Proceedings一9th Russian-Korean International Symposium on Science and Technology,2005.

作者简介:享B东兵(1971一),男,高级Z-程师。1993年毕业于山西矿业学院(硕士学位),现在晋城煤业集团成庄煤矿从事技术工作。

(收稿日期:2010—07—07;责任编辑:姚克)

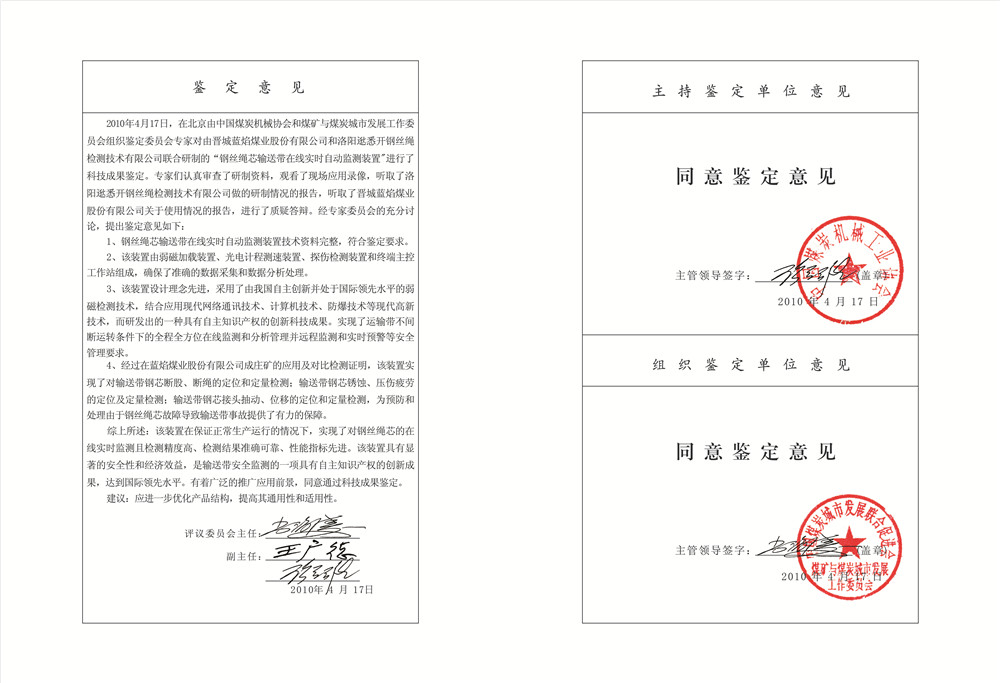

科学技术成果鉴定证书

![5eddaddf405dc.jpg W$%]I7WV`O[F1L97LVQXM[J.jpg](/uploads/img1/20200608/5eddaddf405dc.jpg)