What can

I do-——It can inspect all kinds of wire rope flaws such as internal, external broken wire,

abrasion,

corrosion, deformation, fatigue etc.

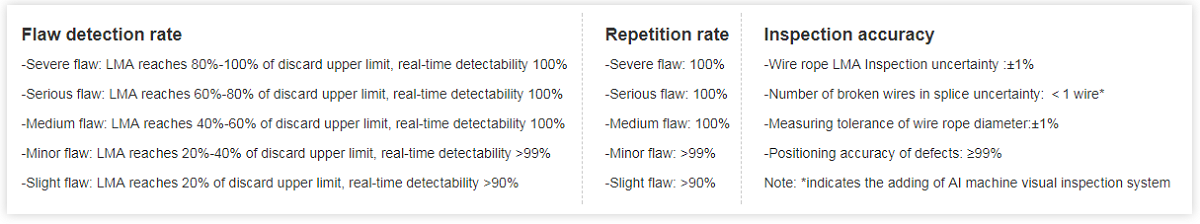

Technical Parameter

1. Product model: TCK.W-DT624

2. Implemented standard: Q/LYWR08-2014 Elevator Wire RopeInspection System Enterprise Standard

3. Operation method: portable, routine inspection

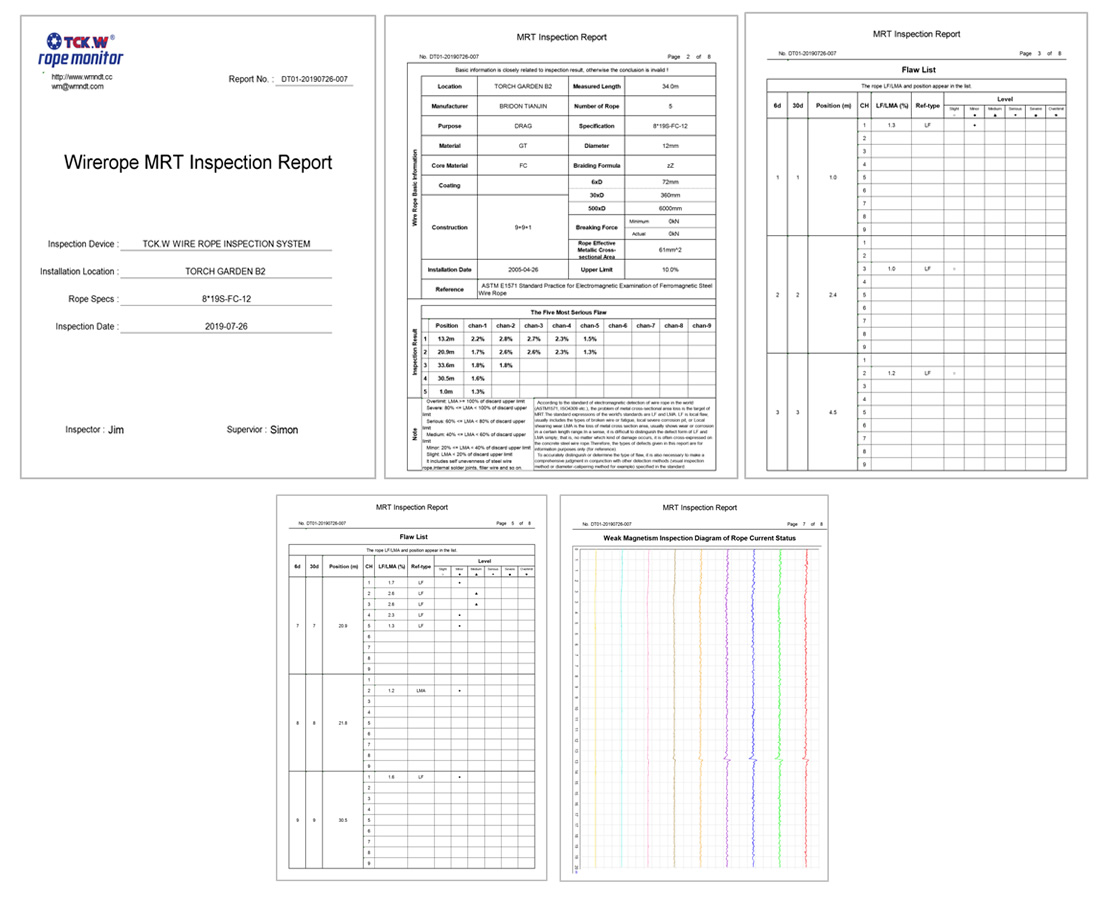

4. Inspection function: quantitative and synchronized inspectionon broken wires, abrasion, corrosion and fatigue for multiple ropes.

5. Benchmarking function: Auto bench marking without need tobenchmark on multiple positions for multiple times.

6. Operation system: Human-machine data exchange can be realizedby connecting inspection device with laptop LAN or through wifi. 7. Display function: inspection curve can be displayed on real timeduring inspection.

8. Retrieval function: can retrieve inspection content on real-time onterminal, including current curve of wire rope, flaw position, flawquantity list and major flaw list. Historic inspection data can also be retrieved.

9. Report function: By connecting with computer through wifi, inspection report can be printed out instantly. Can also print inspection report of any historic point whenever necessary. Inspection report is automatically generated by software and easy to be read and interpreted.

10. Magnetic memory regulation device:the function of regulating memorized magnetic field. Memorized magnetic field can be maintained forever if no external interference.

11. Inspection device: non-contact weak magnetic sensor array. Can collect magnetic energy potential differential information in wire rope and analyze quantitatively.

12. Data storage: 64G Class 10 high speed flash memory

13. Self-diagnosis function:have self-diagnosis function for sensor property, communication modular, storage modular and AD/DA modular.

14. Wide air gap: ≥5mm, Not affected by surface warp, oil and deformation.

15. Device profile dimension(mm):350*230*150

16. Device weight: inspection device 4.6kg, weak magnetic memory regulation device 5.7kg

17.Data transmission: Wifi transmission or USB transmission.

18. Electric magnetic sensing signal-to-noise ratio: S/N>85dB

19. Flaw positioning accuracy:≥99%

20. LMA inspection error:±1%

21.Inspection range: Φ10-30mm

22. Sensitivity of sensor: 1.5V/mT

23. Maximum Sampling rate: 2048 times/m

24.Maximum width of rope displacement:220mm

25. Inspection speed: 0-5m/s.

26. Power supply by Lithium battery: 7.4 V DC

27. Continuous operation hours of battery:≥6hours

28. Ingress protection:IP54