-

来源: 洛阳威尔若普技术检测有限公司

来源: 洛阳威尔若普技术检测有限公司

-

时间:03-27

时间:03-27 -

在线留言

在线留言

-

在线咨询

在线咨询

Time: Feb. 7th 2023

Location: Construction site in Hong Kong

Purpose: to verify TCK.W device on the work site

Device model: TCK.W ZN1650 Portable device

Inspection process:

1. Customer has found a sample rope and tightened the rope to be straight.

2. Customer uses TCK.W magnetizer to magnetize the rope from left to right.

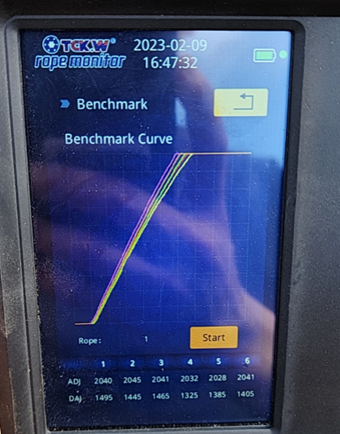

3. Bench marking

4. Customer uses TCK.W detector to inspect the rope from left to right.

5. Inspection result is shown on the handheld display.

6. The rope looks smooth on the surface but the device shows big spike so customer decides to open the rope on the site to verify the defect.

The position of first defect is at 2.8m. The inspection curve is as below.

When customer opens the rope and finds two broken strands inside which is resulted with corrosion.

Conclusion: The rope is suggested to be discarded immediately.

上一篇: Prioritizing Safety in Port Cranes with Portable Wire Rope Inspection Equipment

下一篇: TCK.W has been invited to participate in Offshore Technology Conference 2023